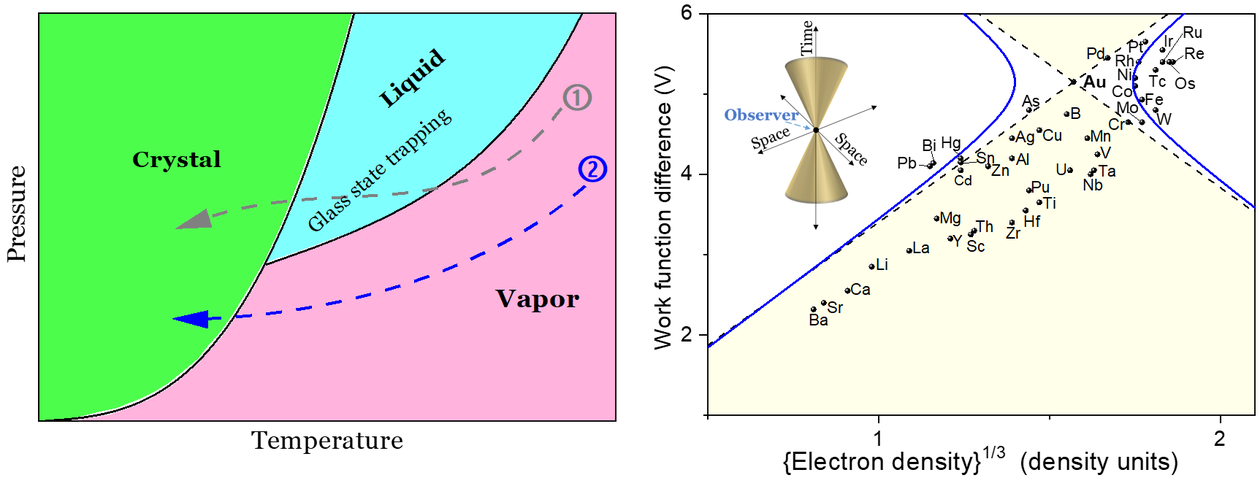

The relentless pursuit of miniaturization in integrated circuit (IC) fabrication is approaching its fundamental limits, constrained by challenges in downsizing, interconnects, and materialization. To transcend these barriers, a paradigm shift toward atomic-level manufacturing is imperative.

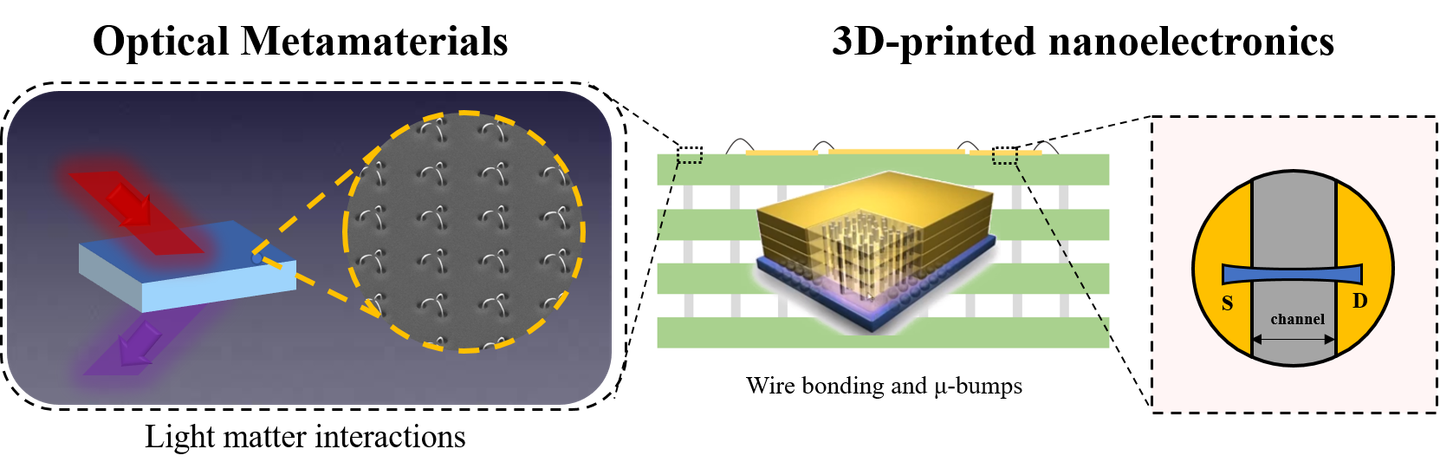

At the Aerosol Intelligence Laboratory (AIL), we pioneer Faraday 3D Printing—a groundbreaking technique designed to meet this challenge. Inspired by Faraday's concept of lines of force, we repurpose these fields as true 3D nano-drawing tools. Unlike wavelength-limited lithography, this method possesses no inherent downsizing limit, directly enabling the assembly of matter at the atomic scale to create expansive arrays of intricate, multi-material nanoarchitectures.

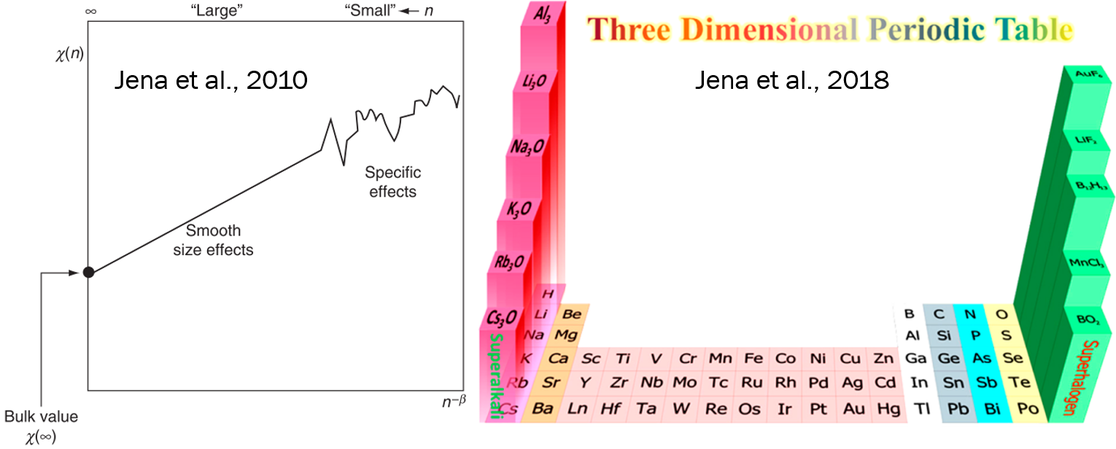

Our proprietary system achieves unparalleled flexibility by precisely manipulating electric and flow fields. This allows for high-precision, large-area printing with a vast selection of materials, a prospect previously untapped in nanofabrication. This capability permits the precise tailoring of optical, electronic, and mechanical properties through control of material composition, geometry, feature size, and array periodicity.

We posit that Faraday 3D Printing represents a monumental paradigm shift from lithography to additive, atomic-level manufacturing. This technology is not merely an advancement but a foundational breakthrough, establishing the core research agenda of AIL for the future of nanoelectronics and nanophotonics.